Introduction

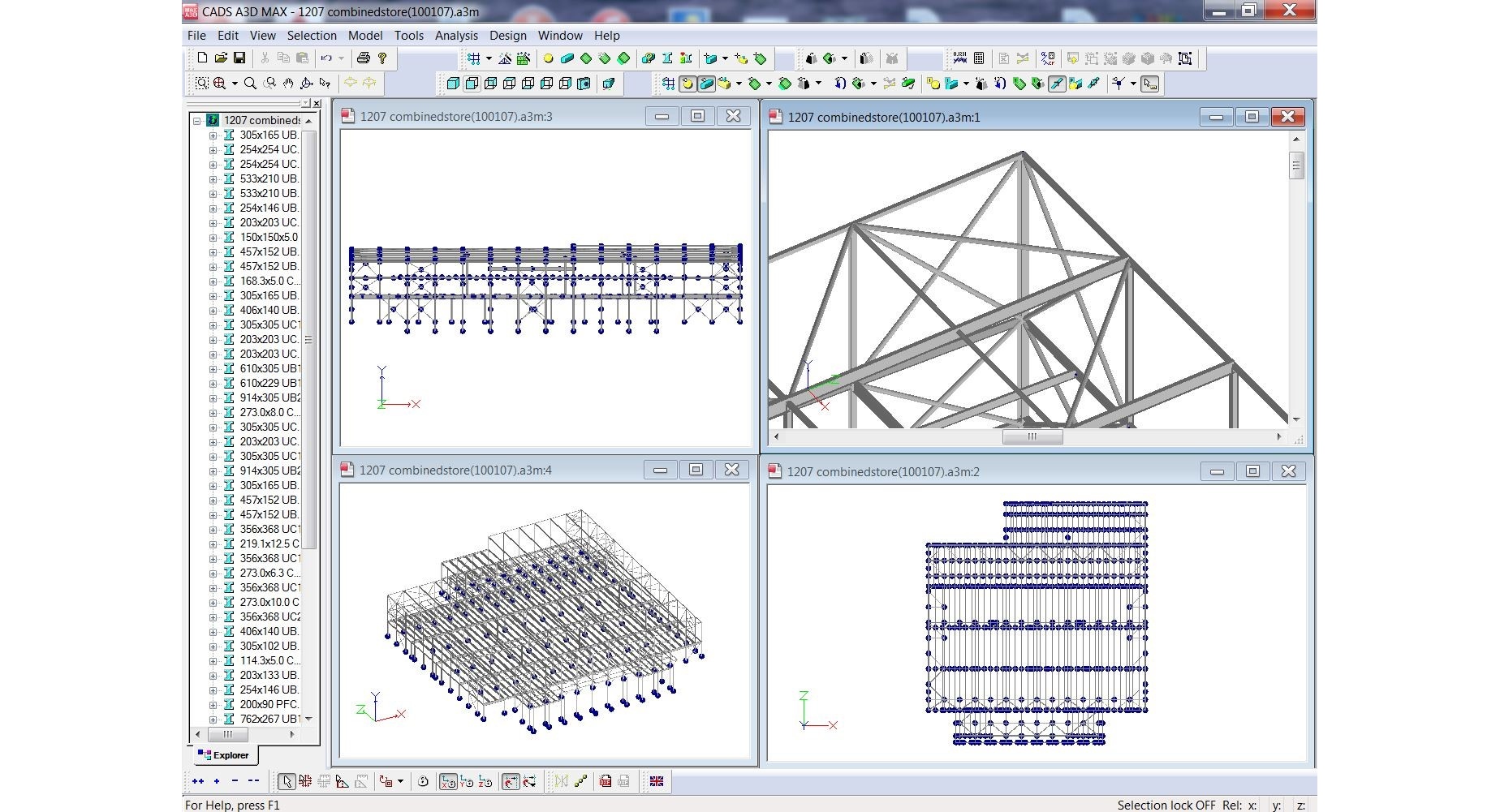

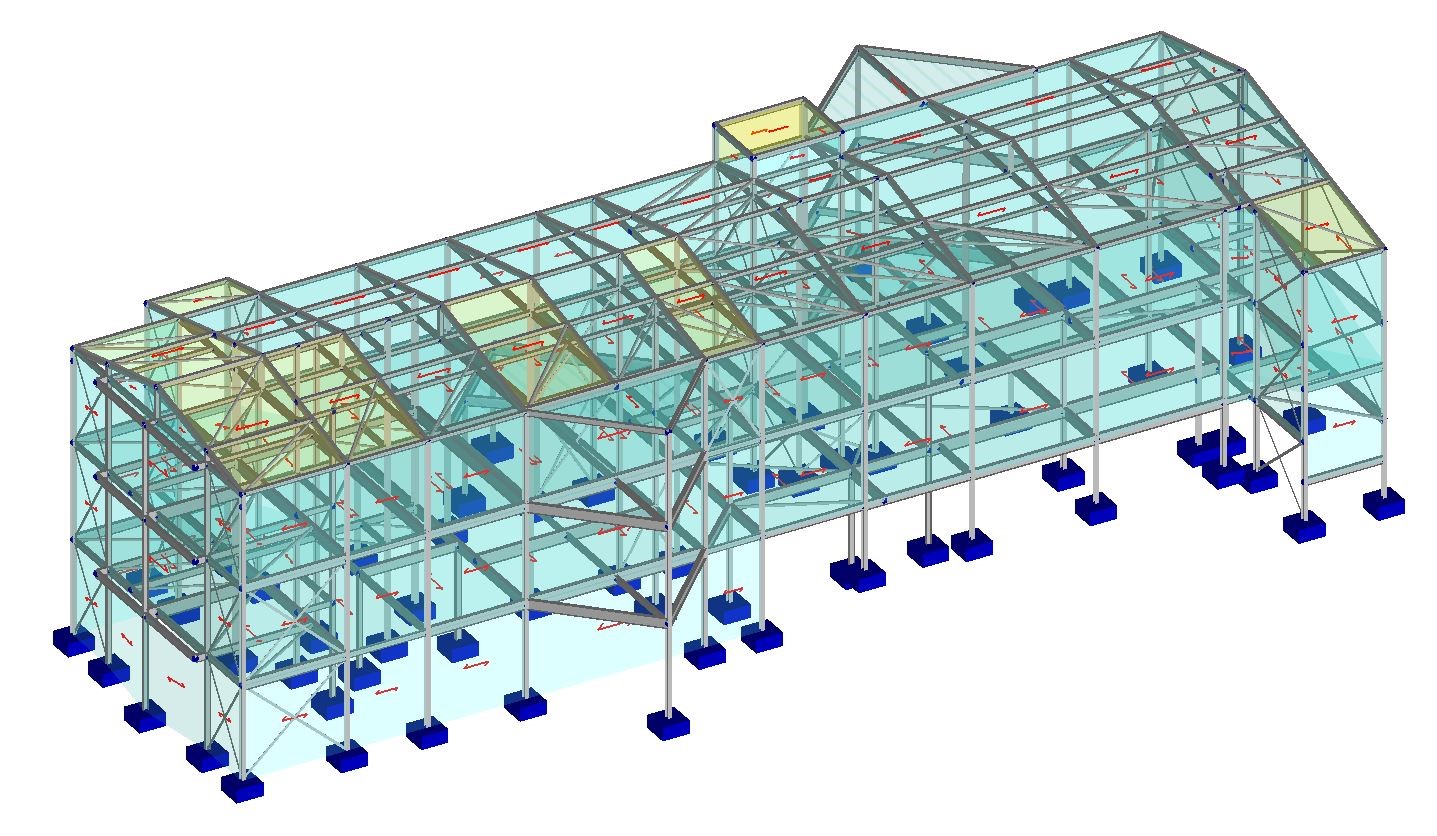

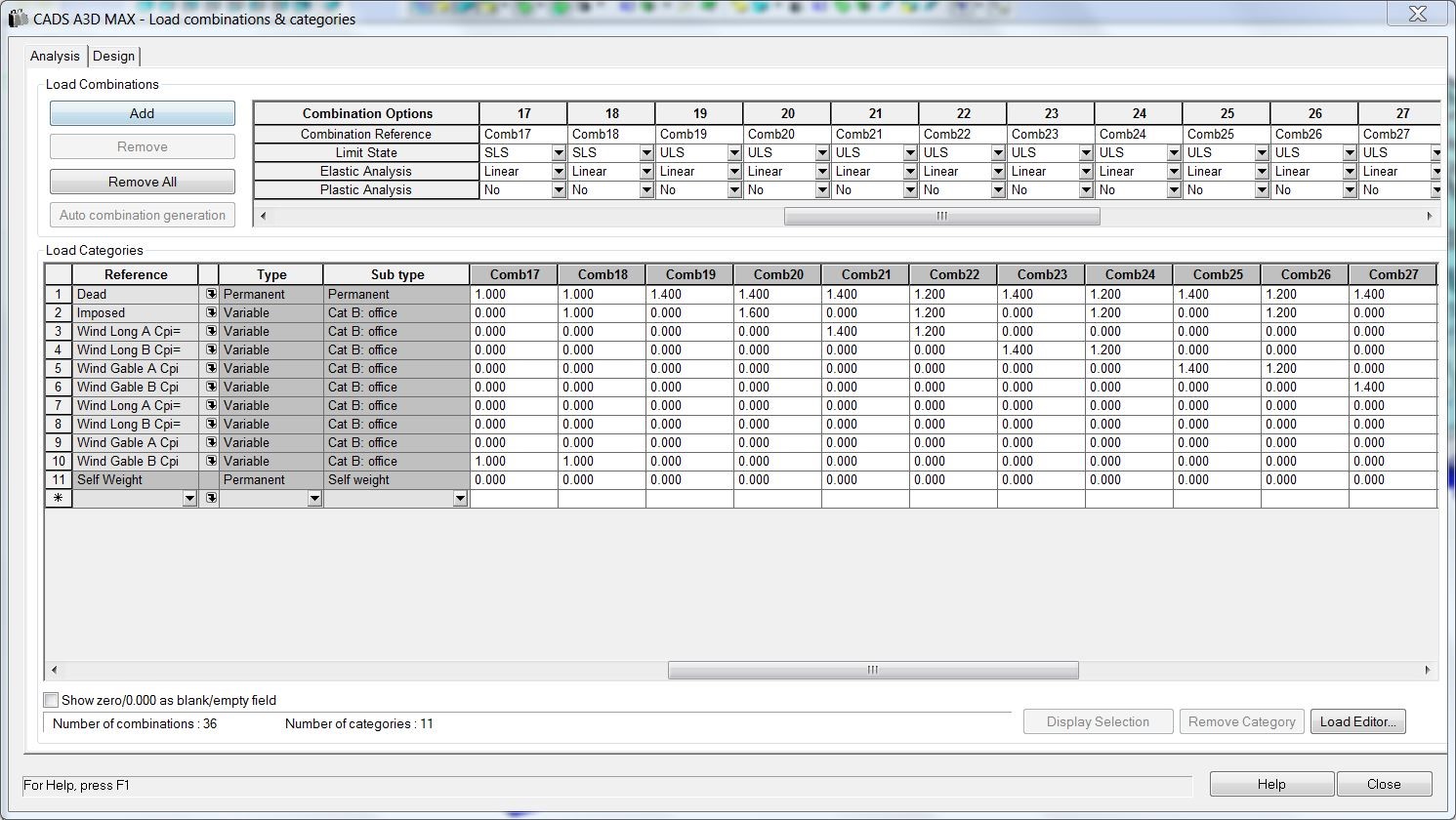

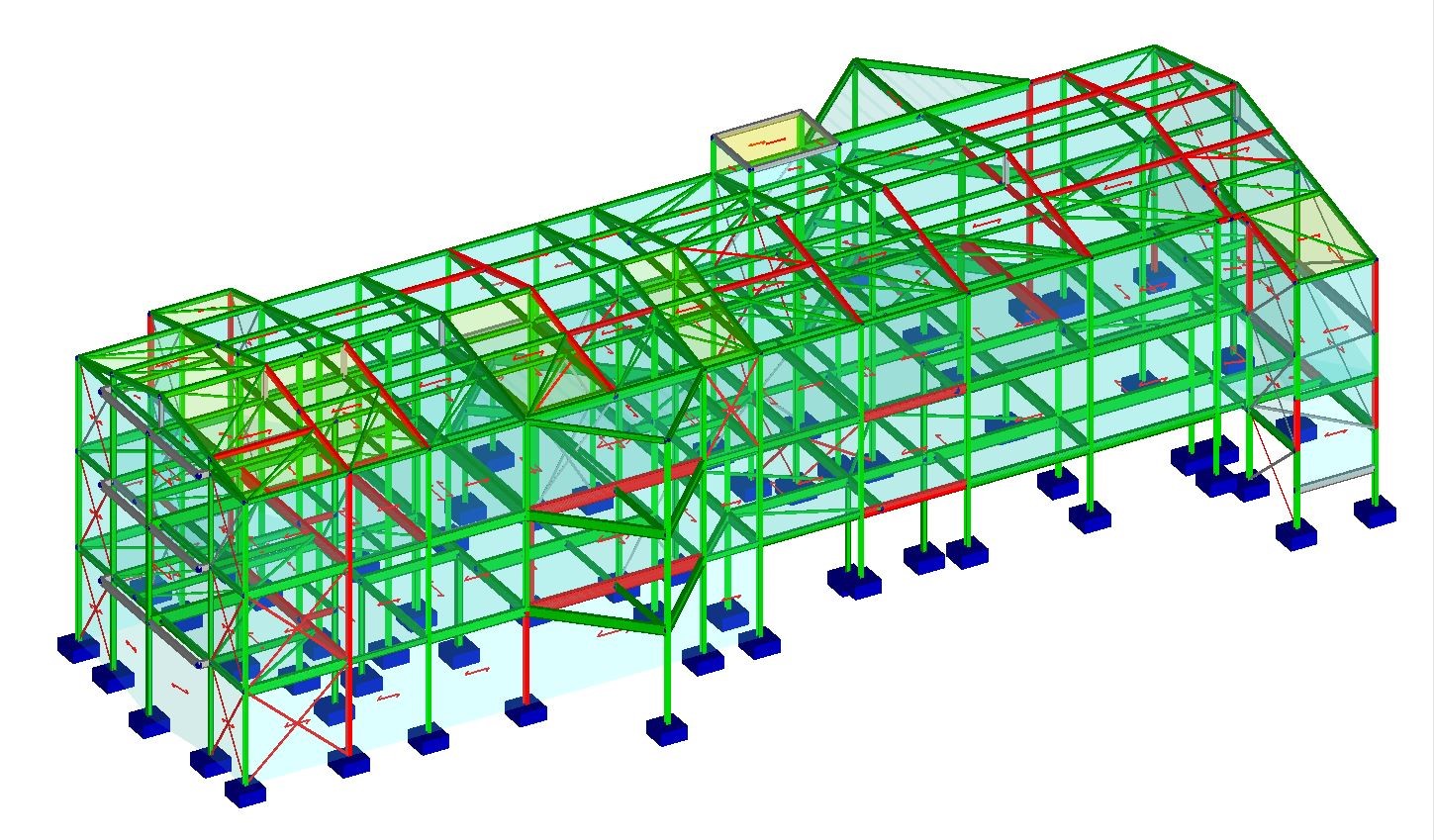

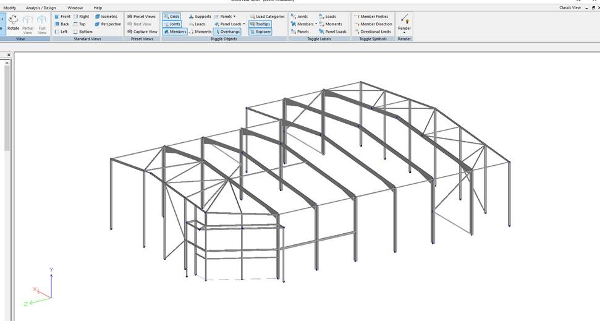

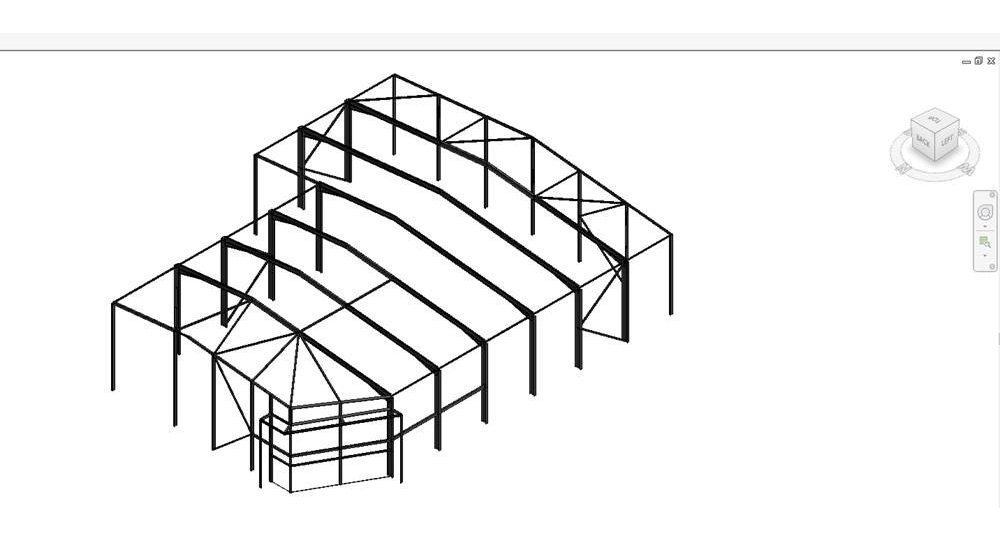

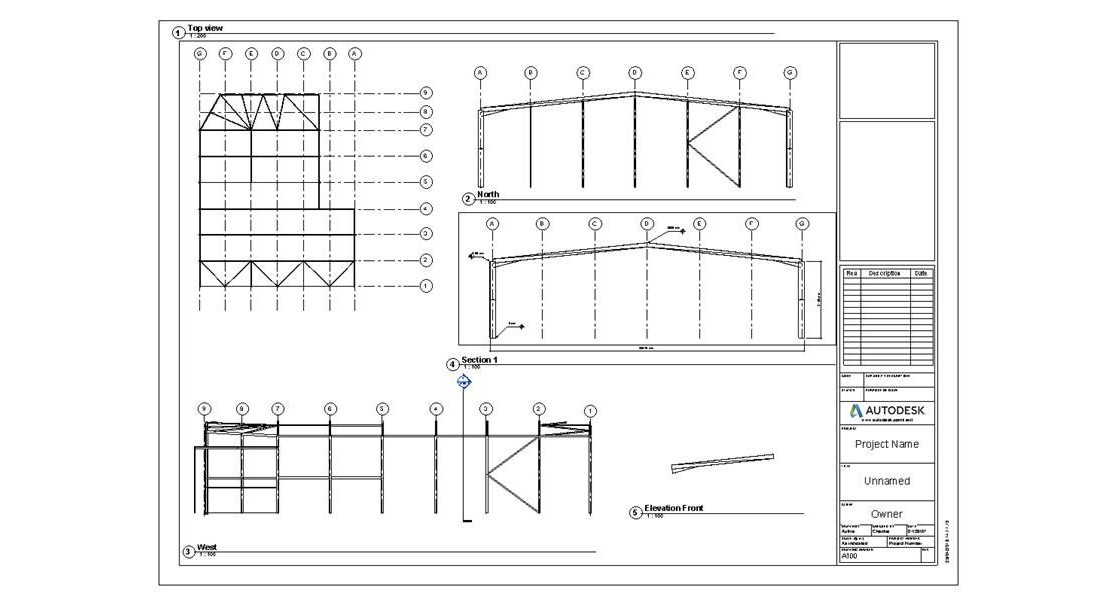

CADS A3D MAX provides a powerful and flexible frame analysis package for 2D or 3D, elastic/plastic/P-delta analysis and can solve any size job with no limit on the number of members or load combinations. Links to CADS design and detailing software as well as Revit compatibility via an IFC export.

Summary

- Rapid 2D & 3D building modelling

- Use for simple beams or complex frames

- Area load application (kN/m²)

- BS5950/EC3 Steelwork design

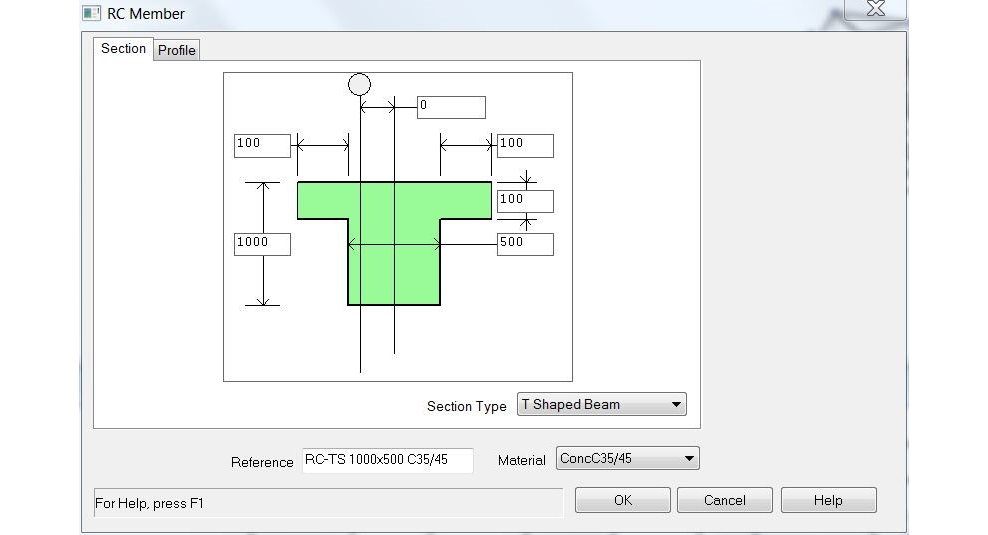

- BS8110/EC2 Reinforced Concrete design

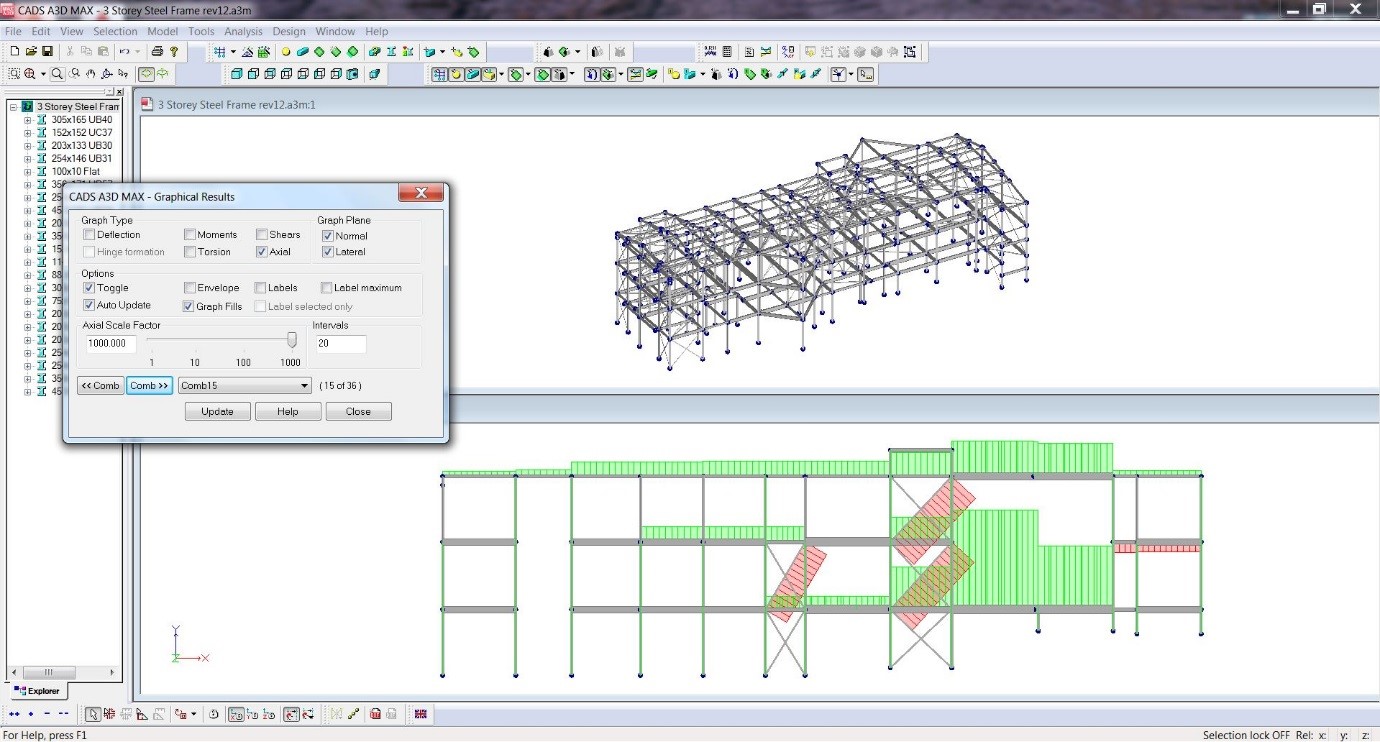

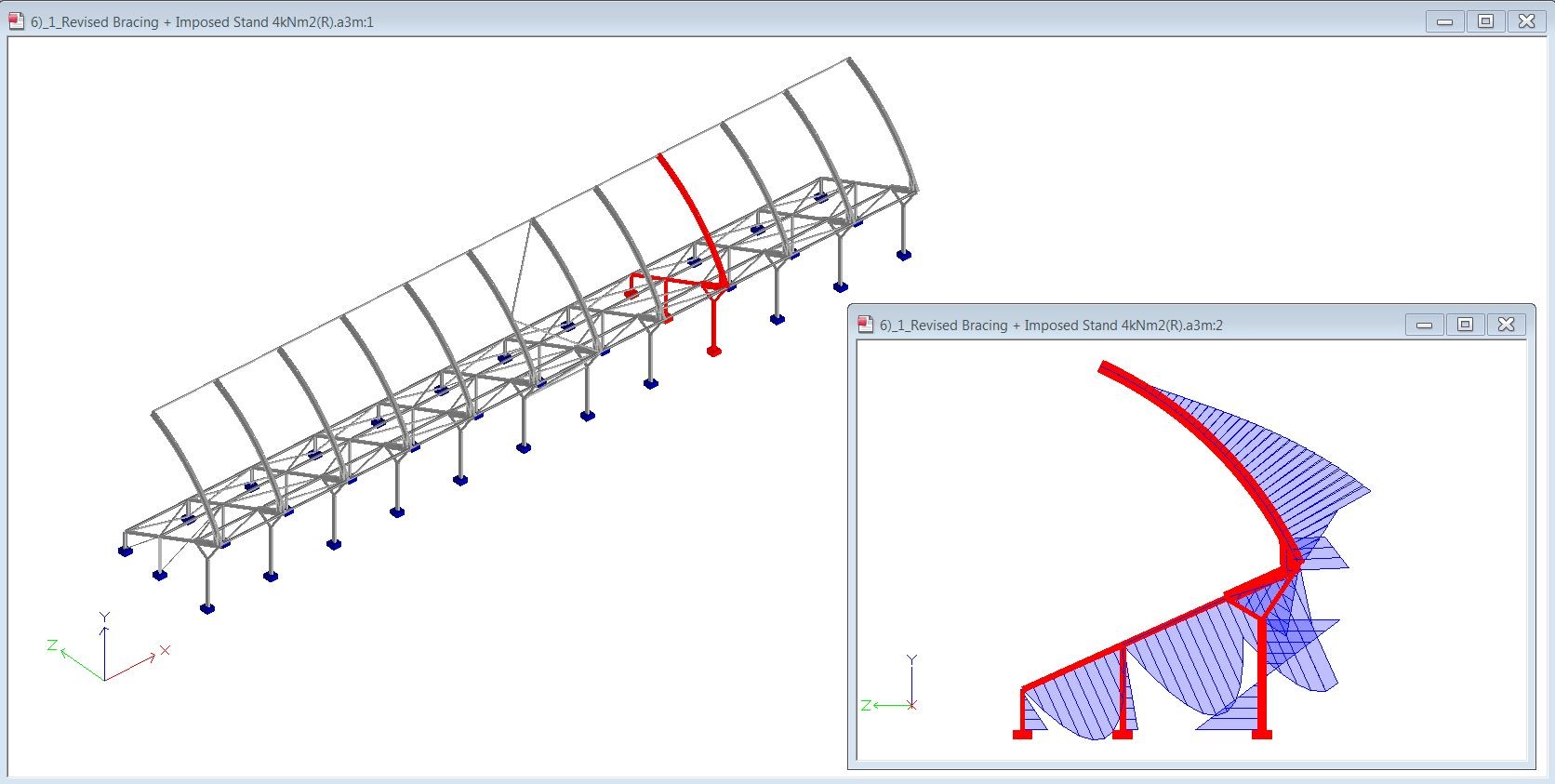

- Flexible graphical display of forces, moments and deflections

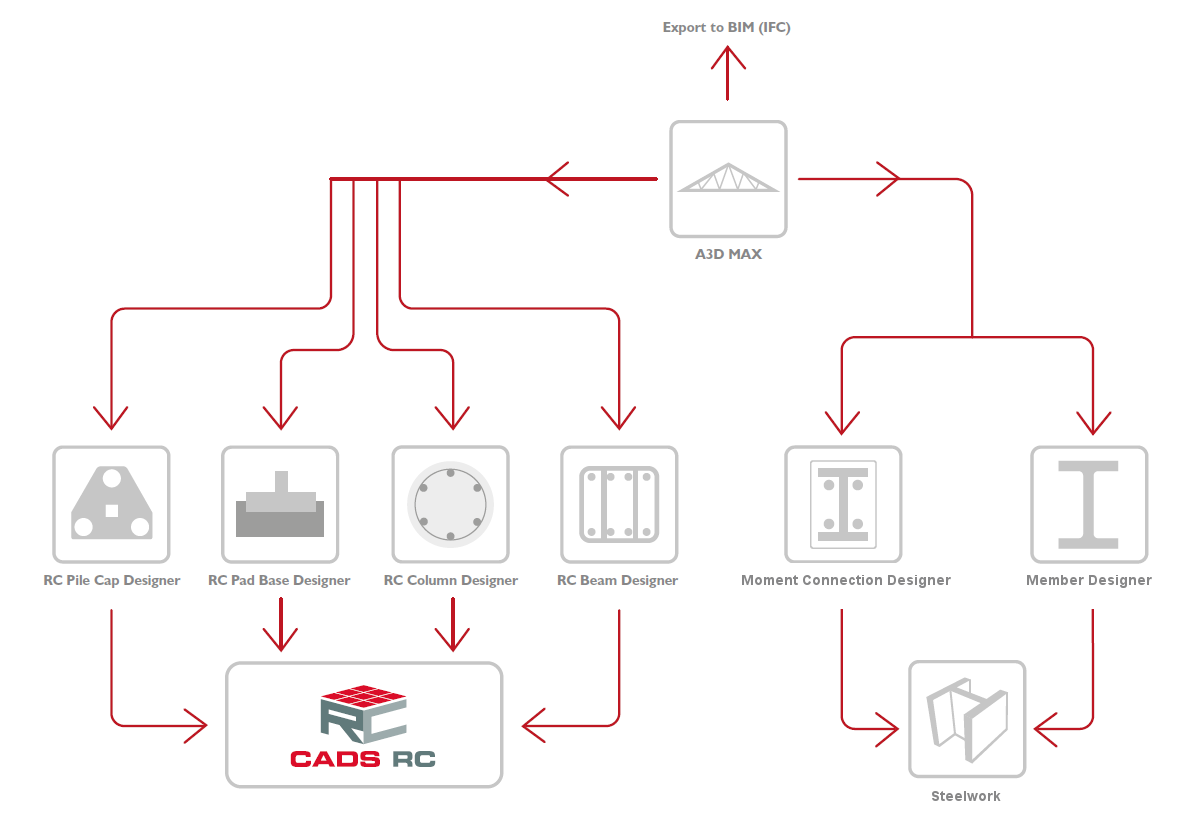

- Integrated with CADS Design and Detailing software

- Export IFC format to link to Revit

- No limit on the number of members per frame

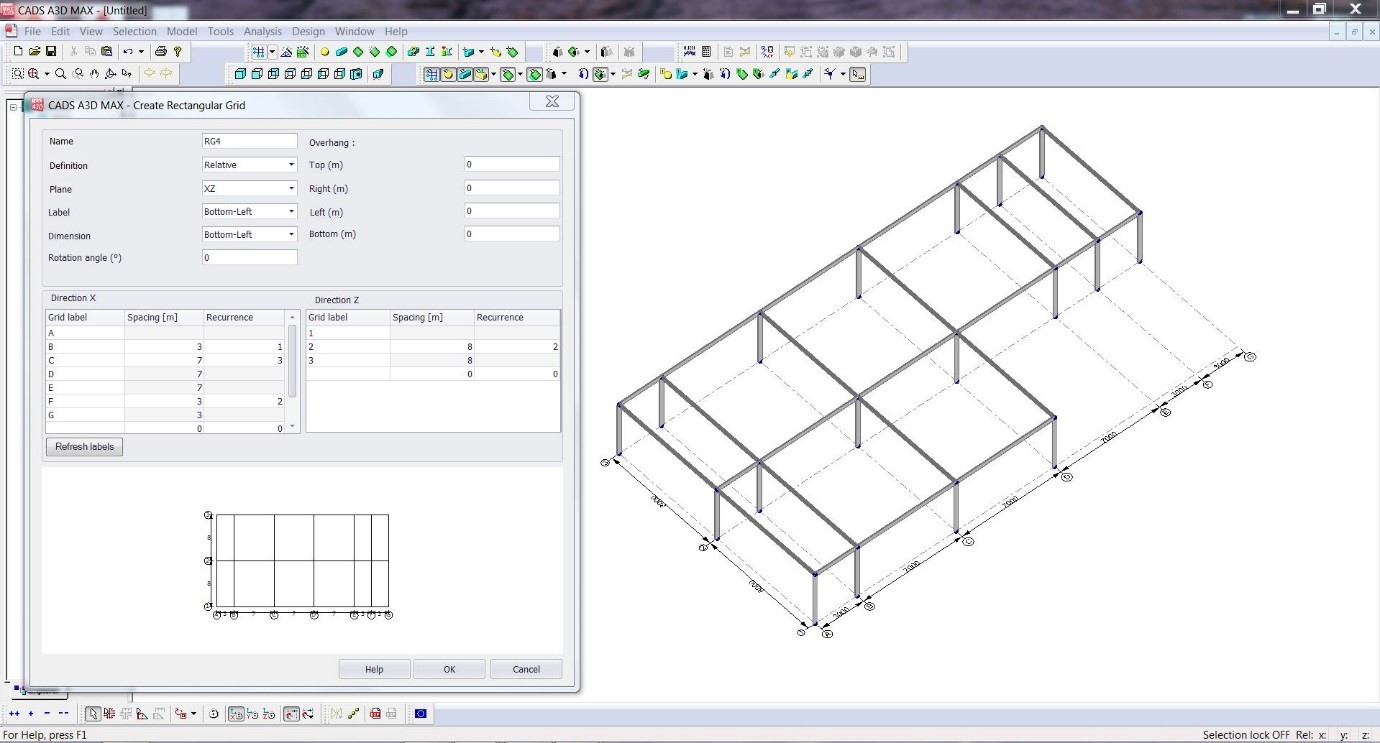

- Fast automatic frame generator macros

- Import from AutoCAD and spreadsheets

- Intuitive user interface makes learning easy

Full description

Productivity is enhanced by an extensive selection of 2D and 3D frame generator macros. Users follow a simple procedure to produce the complete frame geometry in a few seconds. Additional sub-frames and individual members can be added, as required.

To maximise productivity, A3D MAX allows users to access all data, including geometry, section properties, loads etc., at the touch of a button. When used in conjunction with the extensive on-screen help, the software is very easy to learn, and suitable for occasional users. Wading through reams of results can be a big headache, so the Deflection Limits facility is provided to filter out trivial results and report only the ‘critical’ or ‘failed’ deflections as defined by the user.

The A3D MAX panel feature is a productivity aid which allows single panels or whole floors or walls to be loaded with uniform, patch, point and line loads which the program automatically applies to the supporting beams or columns, thus saving the user huge amounts of time and all without the need for FE plate analysis. Floors and groups of panels may be defined as rigid plates to model the diaphragm action of most concrete floor systems.

A3D MAX includes functionality that enables users to define members as tension / compression only elements in their structural models, so that they can be designed and checked accordingly.

A3D MAX enables users to define supports as ‘lift-off’ in their structural models, enabling the condition to be detected and designed more easily and safely. This is especially valuable in more complex structures where ‘lift-off’ may not be anticipated by simple inspection.

A3D MAX provides functionality to model the rigidity of practical steelwork connections enabling the benefits of semi-rigid connections to be exploited as well as the usual rigid and pinned options.

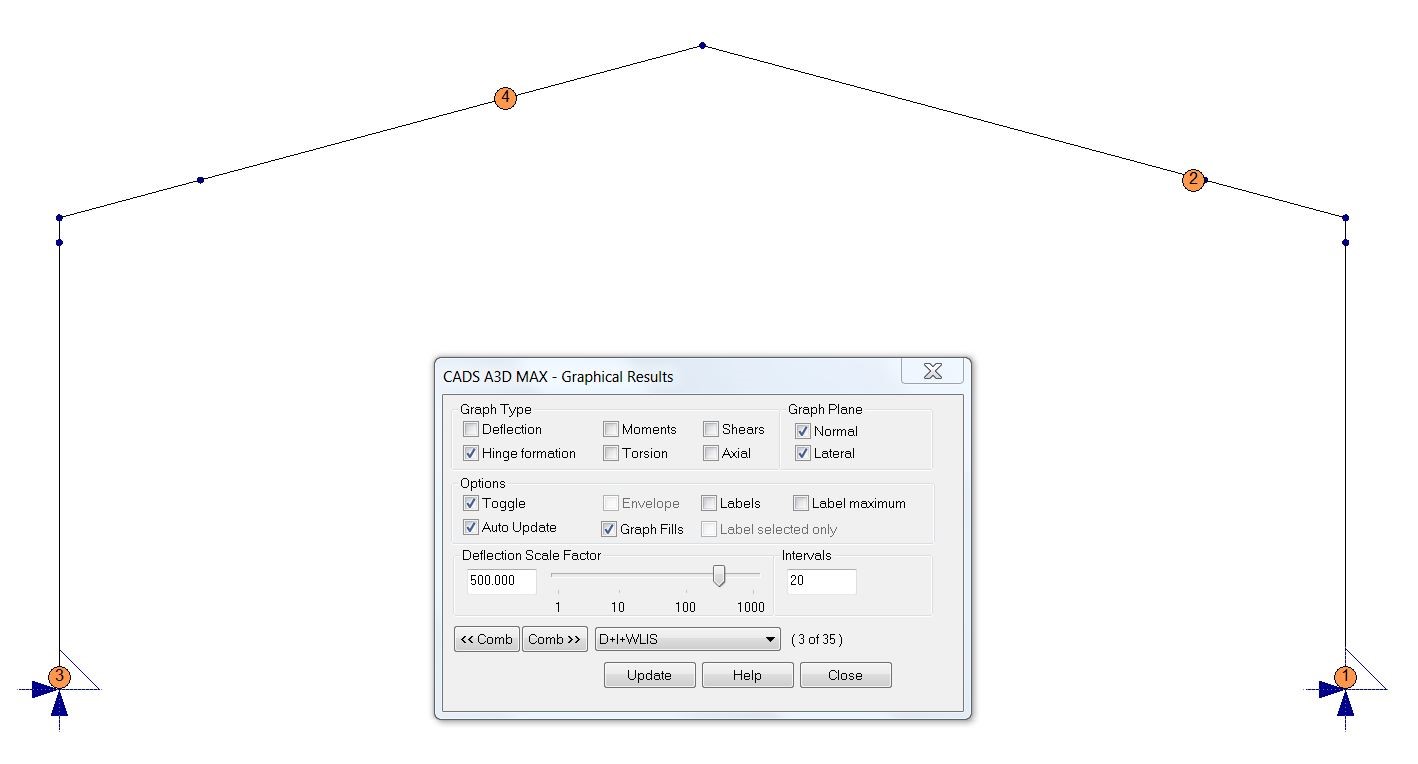

A3D MAX plastic analysis features provide the following results for steelwork and other structures:

- Load factor at which the first plastic hinge forms for each load combination

- Full history of plastic hinge formation up to collapse for selected combinations

- Bending moment and other results for any member at any stage up to collapse

A3D MAX provides user friendly access to the full elastic-plastic P-Delta analysis functionality previously only available in much more cumbersome and expensive software. Users may elect to include or ignore P-Delta effects in elastic or plastic analysis.

In recent years the ‘elastic critical load factor’ has become an important parameter for determining the sensitivity of frames to second order buckling effects. A3D MAX provides an independent analysis feature to automatically determine lambda crit for selected load combinations by incremental second order elastic analysis. The load factor of the lowest buckling mode is detected. For unbraced frames this will be a sway mode and for braced frames a non-sway failure of the frame or a critical member will govern.

The software provides designers with an option to ignore the torsional stiffness of the frame members where torsion is not a primary load path. The removal of torsional moments from the frame is balanced by an increase in some of the bending moments. This simplified analysis is permitted by BS 8110 Part 2 Clause 2.4.1 and is mainly useful in reinforced concrete frames to avoid designing for torsion.

When necessary, A3D MAX is able to carry out incremental elastic-plastic analysis of structures containing tension-only members and lift-off supports. Similarly, elastic critical load determination can take account of directional members and lift-off supports.

The CADS Design Wizard allows members and supports to be grouped for common design and batch processing of steel members and concrete bases.

A3D MAX can also be integrated with other engineering software from CADS or other suppliers. A3D MAX links with the CADS RC Design modules for RC beams, columns, bases and pile caps, through to CADS RC detailing and automatic bar scheduling with AutoCAD. A3D MAX also integrates with CADS Steel Design solutions, offering links to BS 5950 steel member and connection design, and to CADS Steelwork detailing and scheduling, popular with consulting engineers and steel fabricators.

The latest update now allows the export of IFC files. Simply export your model as an IFC file to import into Revit and other IFC compatible software to benefit from their extended capabilities when creating drawings and reports. The exported file could also be viewed on a tablet on site or as a 3D pdf in Bluebeam.

A3D MAX provides engineers with the flexibility to print either a concise or a detailed report.